Have you ever been cleaning out your closet and unsure what to do with your old athletic clothes or beat-up sneakers? Maybe you’re attuned to the waste caused by garments being thrown out and ending up in landfills and wish to avoid making a big problem worse. Innovations in bio-recycling are opening doors to a new solution: recycled polyester.

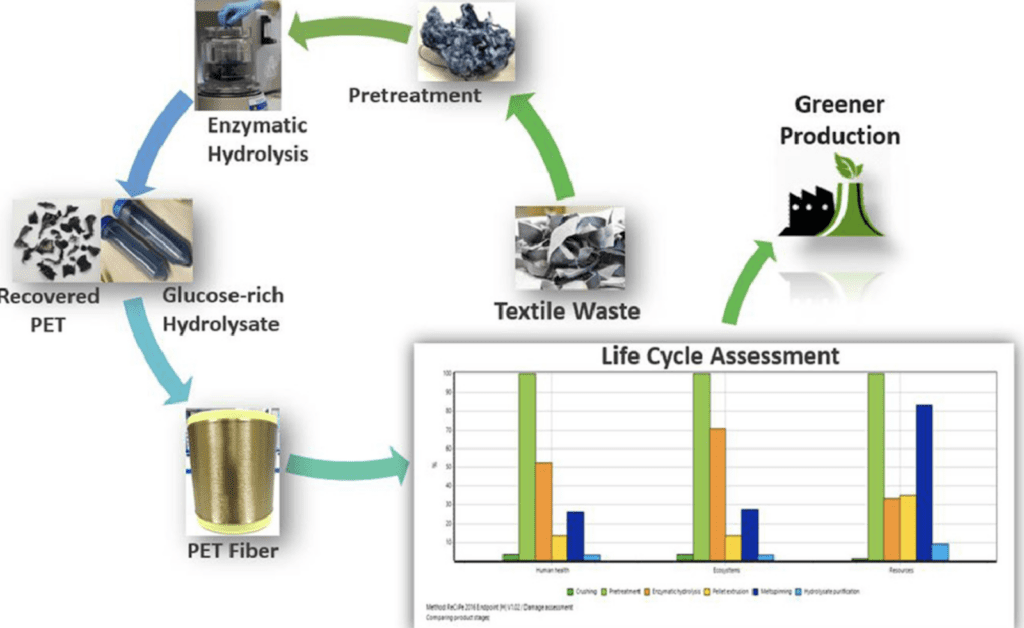

Breakthroughs in enzymatic recycling, a form of bio-recycling, were made by French startup Carbios in 2022. By using an enzymatic process to break down polyethylene terephthalate (PET) into the chemicals needed to make polyester-based garments, scientists at Carbios are finding ways to create 100% recycled and recyclable PET-based clothing without losing any of the quality.

“This is the first organic approach allowing PET plastics and textiles to be recycled infinitely according to a circular economy principle,” the Carbios website said. This process could revolutionize the clothing industry, allowing for more recyclable materials to be used rather than brand-new resources.

Most clothes these days are made with a blend of cotton and polyester and often use petroleum in the production process, making it harder to recycle them.

When factoring in accessories like zippers, buttons, and snaps, it’s even tougher. Not to mention, the fashion industry is plagued by what’s trendy in the consumer marketplace. Recycled clothing can seem unfashionable and lacking quality. Carbios’ bio-recycling could change that.

The process is not a new concept; scientists have researched plastic-eating enzymes for decades. Studies have been conducted about the fashion industry to determine the sustainable viability of the process to reduce waste from discarded clothes and shoes. A big issue for implementation is scale.

“The brands can use plastics to make fibers, but they don’t have a solution for fiber-to-fiber recycling at scale,” Emmanuel Ladent, Carbios CEO, said in an interview.

That’s what Carbios wants to change, especially with plans to open a new plant in France’s Meurthe et Moselle region in 2025.

The company also has a fiber-to-fiber consortium with brands like Puma, Saloman, Patagonia, On, and PVH Corp., a solid backing to make changes in the textile industry.

“The Carbios belief is that we can achieve more as a collective,” said Ladent said in a press release. “That’s why we rally forces with our Consortiums to advance our unique technology, and ultimately switch to a more sustainable industry, benefiting citizens and the environment.”

The waste issue doesn’t just affect Europe. The U.S. produces around 34 billion pounds of garment waste annually. Recognizing the problem, the Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment (BOTTLE), in collaboration with the Department of Energy, is working alongside national laboratories and U.S. and U.K. universities to develop new solutions for large-scale bio-recycling, and enzymatic recycling is on its docket.

Enzymatic recycling offers a long-term solution to the fashion waste issue. Unlike using upcycled plastic bottles for polyester, it helps to negate the waste generated by throwing out clothes. This type of scientific breakthrough could reinforce the point of donating used clothing but with a much more impactful reason to do so.

“In the traditional recycling world, the solutions are not circular. You can recycle materials one, two, three times, and then it’s over,” said Ladent. “With our technology, it’s almost infinite.”