The best part of producing our Made in America American Innovators series is the incredible pioneers that we get to know along the way. And, Dr. Habib Dagher stands tall among them. Dr. Dagher built the University of Maine’s Advanced Structures and Composites Center, where he is a champion for developing sustainable infrastructure and energy systems. From bridges to boats to wind turbines, Dr. Dagher and his team are finding new and environmentally friendly ways to optimize structures, building materials, manufacturing methods, and more. And, one of the coolest innovations in this quest is the focus of our episode.

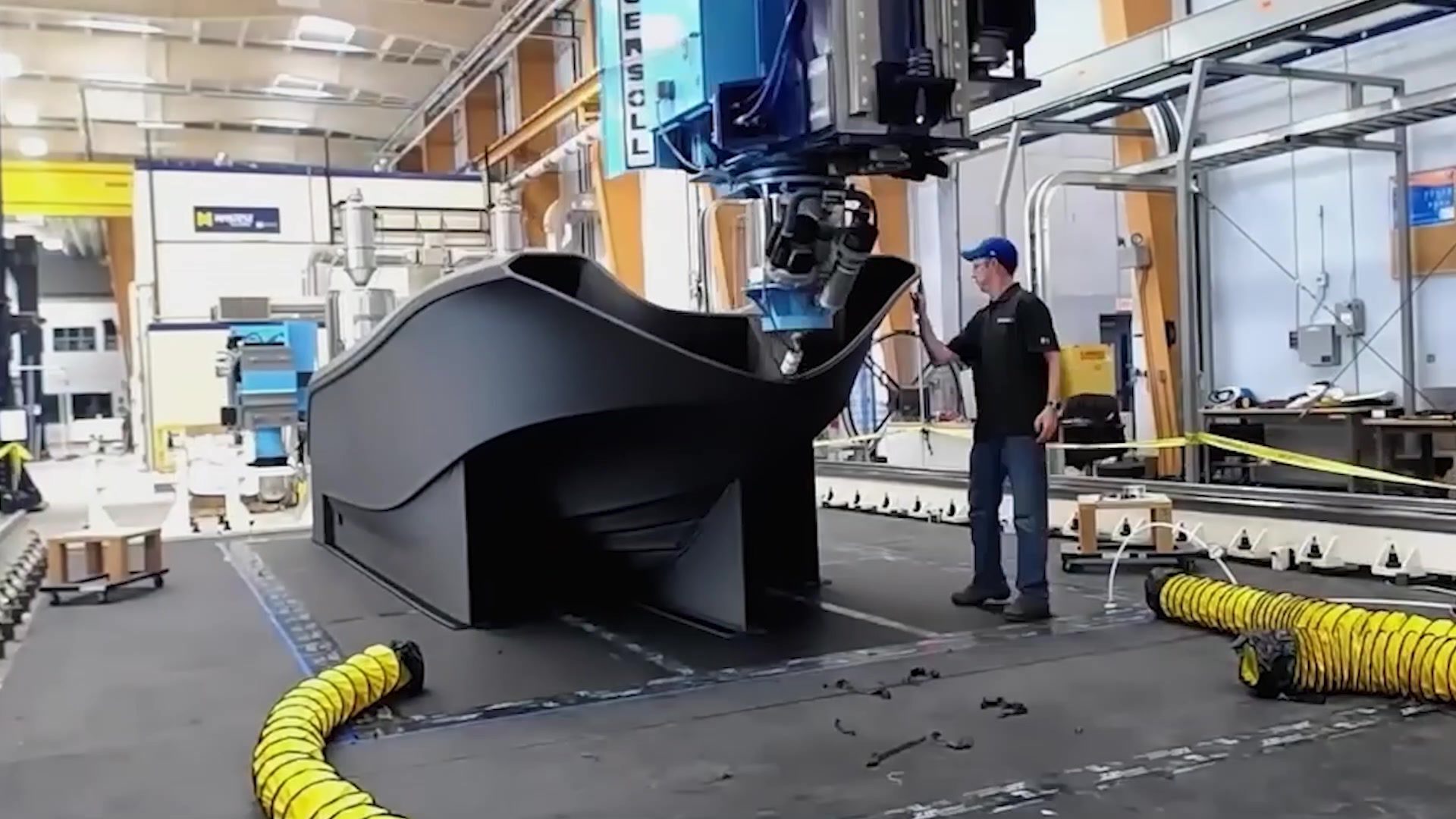

In Maine, everyone needs a boat, right? The researchers at UMaine’s Advanced Structures and Composites Center set out to find a new, sustainable, and remarkably cool way to do this faster than ever. They printed it – And in the process, earned themselves a #GuinessWorldRecord, or two! Trading shifts through the night, the team printed a seaworthy vessel in under 72 hours. At 25′ long, weighing 5,000lbs, the 3Dirigo is currently “docked” inside the University of Maine’s Advanced Structures and Composites Center, 100,000 square feet of well-measured curiosity, where 260 scientists and a whole lot of students ask big questions and solve big problems for #NASA, the #USMilitary and 500 plus corporations. It’s also home to the world’s largest #3Dprinter (just big enough to print a record-breaking #boat).

Not only is UMaine making great strides for the world of large-scale 3D printing, they’re doing it sustainably, testing bio-based feedstocks to replace traditional petroleum based printing. As researcher James Anderson says, “fully bio-derived, fully recyclable, that’s the holy grail.” And that holy grail comes with the added bonus of boosting the bottom line, according to Drew Lyman of Lyman-Morse. The Lyman family has been building boats for 43 years and with new 3D printing molds, they’re saving time, money, and precious resources.

Today, researchers at UMaine are building applications for bio-based 3D printing on an even larger scale, exploring ways 3D printed homes could be an affordable, efficient, and adaptable solution to America’s housing crisis. This is public research and private enterprise at its best, spurring innovation and growth for the Pine Tree State and for all of us.