How does one solve labor shortages? As the majority of industries around the United States begin to ramp up into a full, pre-pandemic swing, a surprising lack of willing workers has emerged in stark contrast to the unemployment highs of last spring. Whether it comes as a result of ongoing government pandemic assistance or is simply a statistical blip that will even out in the coming months, American farms have been among the hardest hit. Some states are using federal pandemic relief funds as a means to boost hourly wages. For example, Oklahoma recently used $5 million in federal pandemic relief funds to boost their farming wages to nearly $20 an hour ahead of the annual state chili harvest.

Perhaps the solution to the lack of farming labor is not a matter of fiscal policy or even a human issue at all. Companies around the world are utilizing artificial intelligence in tandem with industrial robot technology more frequently than ever before, and there is no more relevant area of business for this practice than farming.

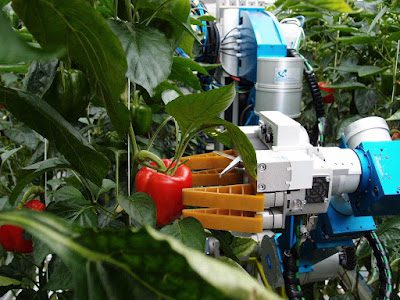

Xihelm, a UK-based agri-tech startup, has developed a robot that uses machine learning combined with good old-fashioned modern engineering to pick tomatoes in place of humans. Although there is something to be said for the meditative aspect of harvesting one’s fruits and vegetables by hand, that feeling tends to dissipate over the hours spent working a multi-acre farm versus a backyard garden. With Xihelm’s creation, farmers can lean on artificial intelligence in times of labor shortages and well beyond.

The startup’s prototype, known simply as Eagle, works in a relatively straightforward manner. It was developed with a machine learning algorithm that was fed countless images and other data that identifies the ripeness of a tomato, data that is then used to inform the robot in real-time as to whether an actual tomato is ready for picking. Eagle is designed to detect a variety of situations, including how to most efficiently pick the fruit without damaging the surrounding crop, all while evaluating the fruit on several metrics like shelf life and taste. The machine is also capable of noting different indicators of disease on a crop, which can then be passed on to the human in charge. Eagle’s algorithm improves with every new variable recorded, which makes harvesting even better. The machine collects an average of 300 new variables per harvesting session, so it’s no surprise that its harvesting efficiency has improved by a factor of seven since it was first tested in 2017.

Farmers interested in Xihelm’s creation have multiple options at their disposal. While they could simply purchase the machine outright or lease through a “robots-as-a-service” mode. For the consumer, there are several advantages to the latter approach–the cost is based on either volume harvested or area covered, and every aspect of installation, maintenance and monitoring is taken care of by the company’s Field Engineering Team without any headache to the farmers themselves. Most importantly, farmers who may be less receptive to funding high-tech experiments in the wake of the economic downturn are able to participate in a non-committal way. “We see it as a tool to enable us to better operate our business and give us information we haven’t had before,” says Charmay Prout, managing director for Flavorfresh Salads and proud Eagle customer. “We think robotics is where the industry is going”.