(Bloomberg) —

The Argos plant in Rioclaro, Colombia, can churn out as much as 2.3 million tons of cement a year, used to build everything from dams and bridges to skyscrapers and stadiums. That has helped make Argos the biggest cement maker in Colombia—but also a major producer of carbon-dioxide emissions.

The cement and CO2 had been pouring out of Rioclaro nonstop for more than 20 years when the chief executive of Argos met an academic named Karen Scrivener, who had a simple pitch: change the recipe for cement to incorporate clay, and slash the carbon footprint. She called it LC3, or limestone calcined clay cement.

After four years of development, the revamped facility in Rioclaro went online this year, using clay that’s mined about 10 miles away and processed in a newly built kiln. Argos says the technology cuts energy consumption by 30% and reduces carbon output by almost half. “It made perfect sense,” says Tomás Restrepo, the head of the company’s business in Colombia. “Less CO2 means less coal or fuel, so it’s more profitable. Environmental change happens best when there’s also an economic incentive.”

It’s hard to overstate the importance of cleaning up the cement industry. Humans consume as much cement as food—4 billion tons per year—and producing it accounts for about 7% of global carbon emissions. Cutting that will take myriad small steps, from reducing the carbon output of cement plants to revising regulations so they more realistically account for the structural needs of buildings. By some estimates, global cement consumption could be cut in half simply by employing the right cement for each job and not pouring more concrete than necessary.

Concrete “is very cheap, and people systematically overuse it,” says Scrivener, 62, a professor at the Ecole Polytechnique Fédérale in Lausanne, Switzerland. “We can make reductions in producing cement, then in how much cement we put in concrete, and in how much concrete is put in the building.”

Sure, there are alternatives: Norway has built a 280-foot tower of wood, and researchers are experimenting with bamboo, recycled construction waste, and even fungi to develop greener building materials. But it’s unrealistic to envision entirely displacing concrete anytime soon, especially where the bulk of growth will happen in the coming decades—places such as China, India, and Nigeria—which have few choices other than concrete for their homes, hospitals, and highways. “Saying we’re not going to use cement is a bit like saying you can keep using transport but without tires,” says John Provis, a materials science professor at University of Sheffield in England. “We have to make more effective cement.”

Cement is made by mixing pulverized limestone with a handful of other ingredients and burning it at 1,450 degrees Celsius (more than 2,600 degrees Fahrenheit). What results is a rocky substance called clinker, which resembles charcoal briquettes used in backyard barbecues. The clinker is ground into powder and combined with a few other minerals to produce cement.

That process, little changed since English bricklayer Joseph Aspdin patented what he called Portland cement in 1824, is a double-whammy for CO2 output. Both the fuel used to fire the kilns and the limestone itself—formed millions of years ago from marine corals and shellfish—release carbon dioxide when they’re burned. For each ton of cement made, the atmosphere gets 600-800 kilos of CO2.

Concrete, in turn, is made by combining cement with sand and rock, then adding water to kick-start the chemical reaction that allows it to harden into a substance that’s ubiquitous and infinitely versatile. Aspdin, the British bricklayer, chose the name Portland cement because he felt his finished product resembled Portland stone, a sought-after building material in England at the time. His concoction allowed builders to dispense with hauling massive chunks of rock. Instead, concrete is easily transported as a gooey liquid that can be poured and shaped into sidewalks, highways, bridges, building foundations, walls, ceilings, and just about everything else; at least some concrete finds its way into virtually every structure in the industrialized world.

LC3 can reduce the industry’s carbon footprint in two ways: Clay contains very little carbon, so there’s almost nothing released when it’s heated, and it can be burned at a more manageable 800 C, consuming less fuel. “At the end of the day you have to break down less limestone with LC3, and it’s the limestone that gives you most of the CO2 emissions,” Scrivener says in her Lausanne office, a jumble of books, files, papers, and empty tea mugs and water bottles. “Sure, you need heat to make it, but not as much as you do for Portland cement.”

The introduction of carbon taxes and trading schemes will drive adoption, Scrivener says. In Europe, industrial sites such as steel mills and cement plants are allowed to belch out a certain amount of carbon. If they emit less, they can sell their extra capacity, but if they exceed their ration they must buy permits from another producer. In the past three years, carbon prices in Europe have more than tripled, and they’re likely to continue rising as the EU ratchets down the limits.

“Things will be much tighter, particularly in Europe, and that will have a bigger impact on decision-making,” says Ian Riley, CEO of the World Cement Association, a trade group. “LC3 will give us a bit of time, though we will need other stuff.”

To hear Scrivener tell it, there are virtually unlimited supplies of clay around the world, much of it already mined and available as material rejected by the ceramics industry or paper producers, who use it for coatings. Many concrete makers have tons of clay sitting alongside the sand and gravel in their quarries.

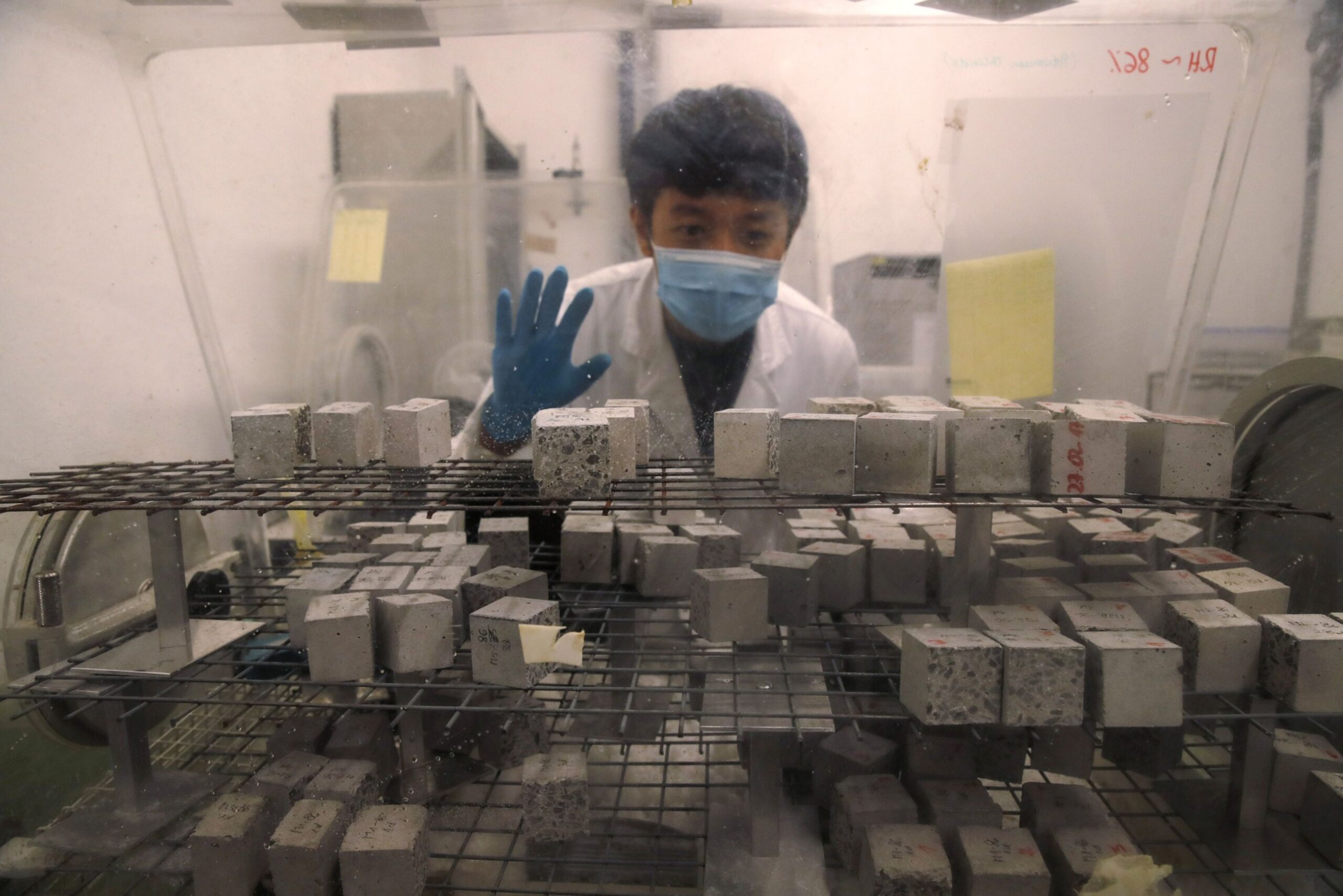

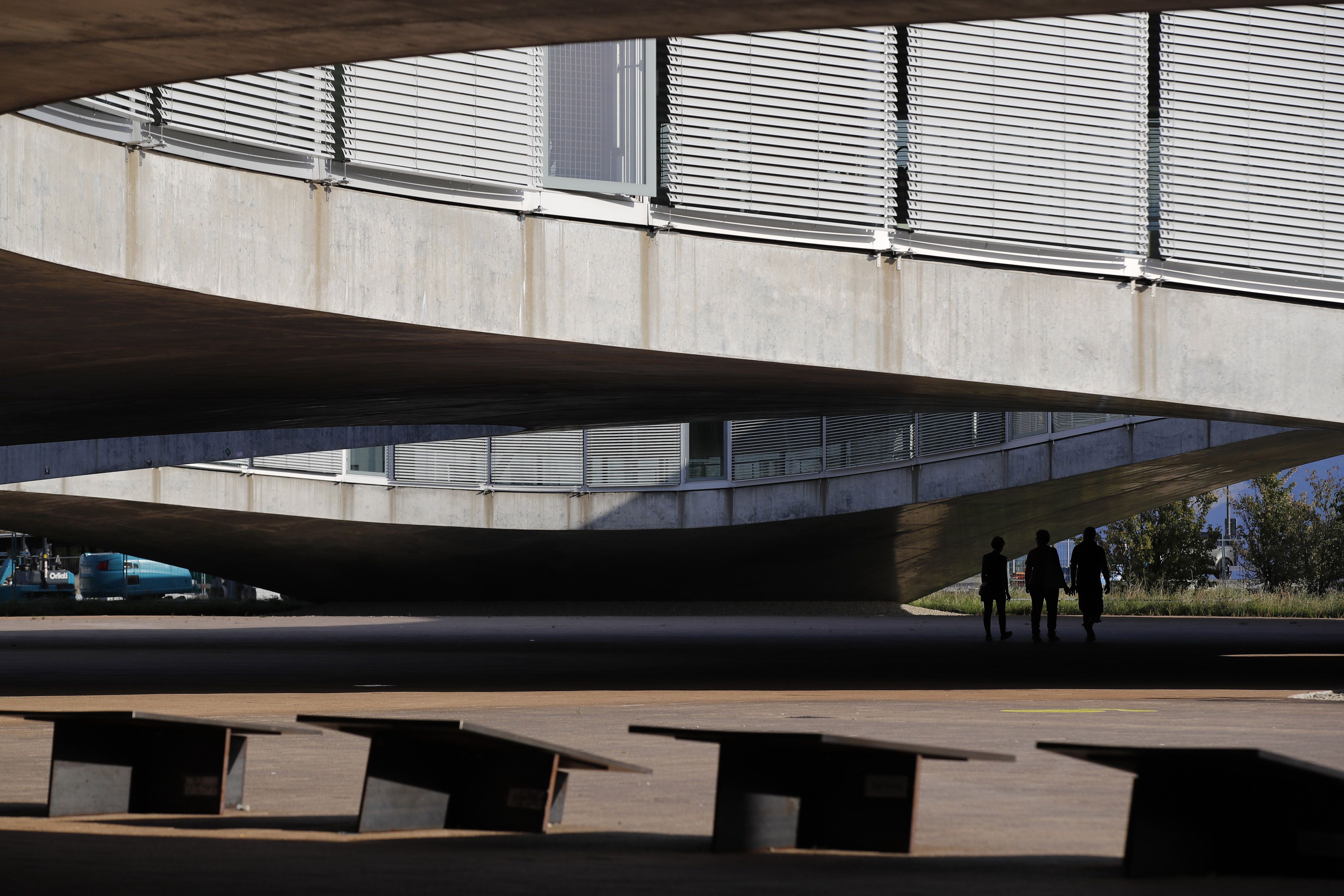

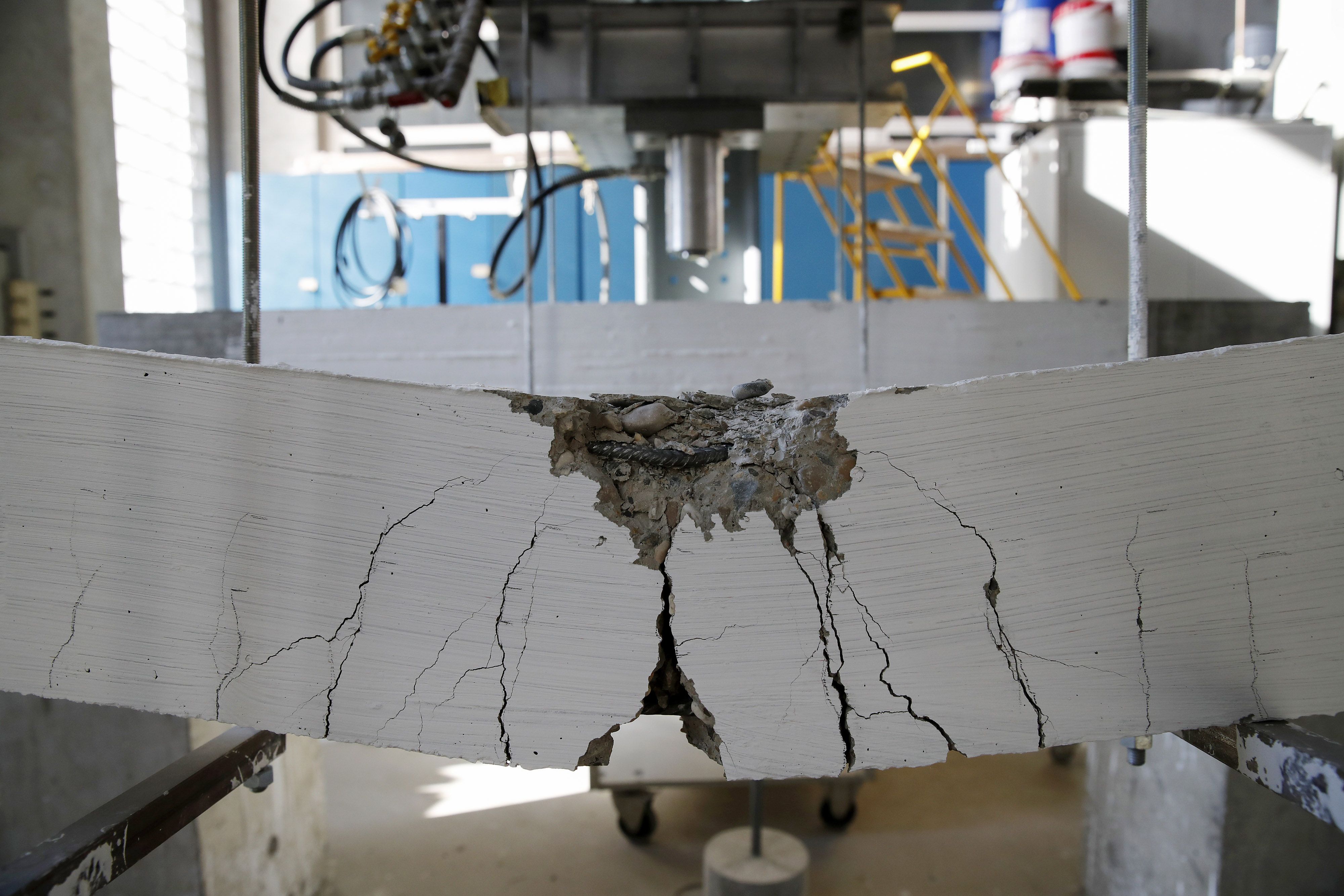

At Scrivener’s three-story lab at EPFL, an austere expanse of (yes) concrete with views across Lake Geneva to the French Alps, students mix up batches of cement and evaluate them with precision instruments such as scanning electron microscopes and spectrometers. One of the lab’s early tasks was to test materials for Switzerland’s hydropower dams, so in one corner there’s a pool where concrete samples have been sitting for decades to see how they hold up. (They’re doing fine, says Franco Zunino, a Chilean grad student who has been working with Scrivener for four years.). A hot room accelerates the aging process to study long-term durability. In the basement, massive machines smash or compact samples to test their strength.

In the LC3 effort, those machines have proven “that we can make stronger cement with less clinker,” Zunino says.

The Argos plant is the first large-scale calcined clay production facility, but more are being built around the world. Portuguese producer Cimpor is doing test runs at an LC3 plant in Ivory Coast. Lafarge-Holcim, Europe’s biggest cement maker, expects to add clay kilns at plants in France and Switzerland next year. Cuba is building more than 20 smaller plants that will make a clay mixture that can be combined with standard cement on building sites—at a cost that’s about one-fifth lower than traditional formulas, according to Fernando Martirena, a Cuban engineering professor who has worked on the idea for more than a decade.

“We’ve used this cement in every possible way,” Martirena says. “We’ve made concrete blocks, polished concrete floors, even an entire house.”

Scrivener can be startlingly blunt when defending what has become her life’s work: At conferences, she’s known for outbursts such as, “That’s the stupidest idea I’ve ever heard.” She says the work of a colleague who backs a rival technology “borders on the criminal.” Of another researcher’s theories, she says, “It’s obvious this is going nowhere, yet these people have built their academic reputations on these materials.” She sees calcined clay as the only real hope for an industry that’s slow to change.

Not everyone is as enthusiastic. Concrete made with LC3 often exhibits less strength than traditional formulas in the first seven days, says Vanderley John, a professor of building materials at the University of São Paulo in Brazil. The strength can catch up later—it takes a month or more for concrete to fully set—and can be boosted with additives or higher quality clay. But delays are costly. “The shorter the construction period, the better the return for investors,” John says.

And Brazil’s Votorantim Cimentos says its program using a technology similar to LC3 has been slowed by a lack of appropriate clay. “It’s not as easy as Karen says,” says Wolfram Schmidt, an engineer with Germany’s Federal Institute for Materials Research and Testing in Berlin. “Every clay is different.”

Even Scrivener acknowledges that LC3 is only a partial solution, which is why researchers around the world are looking for other ways to cut the industry’s carbon emissions. One option is volcanic ash—so-called pozzolana, named after the Italian city of Pozzuoli, near Mount Vesuvius—the key ingredient in the cements the Romans used to build their empire. And companies have long replaced some clinker with slag waste from iron smelting or with ash from coal plants. Both work well but supplies are dwindling, says Wolfgang Dienemann, research director of HeidelbergCement. “Slag is getting more expensive and fly ash is disappearing,” he says. “We are getting to the point where calcined clay is increasingly relevant.”

At Lafarge-Holcim’s sprawling research lab just outside the French city of Lyon, some 200 scientists—Scrivener was once among them—are working to reduce the company’s CO2 emissions by 15% by 2030. More than two-fifths of Lafarge’s 1,300 patents on cement and concrete production serve to curb carbon output, says research chief Edelio Bermejo. “We have to promote greener solutions,” Bermejo says. “But we have to do it without compromising quality.”

The lab’s dozens of projects range from 3D printing of concrete elements to alternative ways of heating cement kilns, such as burning garbage or old tires. One group is making concrete that requires less water. Another adds wood chips to the mix. A third is exploring better ways to grind the sand and gravel so less cement is needed to make concrete.

In a warehouse-like room, Vincent Meyer and his team are turning an old problem with concrete into a solution. Over time, concrete reabsorbs part of the CO2 released in producing cement, making it more acidic, which can corrode steel reinforcement bars inside. Meyer uses rubble from demolished buildings to soak up carbon from the smokestacks at cement plants. “One ton of recycled concrete can absorb 50 kilos of CO2,” he says.

Something along the lines of Meyer’s work—what the industry calls carbon capture and storage—will be needed to get cement production to net-zero emissions. The idea is to separate out carbon dioxide, compress it, and put it deep underground, probably in depleted oil and gas wells. The International Energy Agency says carbon capture will account for 60% of emissions reductions from the cement industry between now and 2070, though the technology remains far from mature.

For Scrivener, the idea of using clay to make cement seemed promising, but it suffered a fundamental problem: the resulting concrete wasn’t as strong as traditional varieties. Then in 2009, Scrivener had what she calls her “aha moment.” By adding a little unheated limestone to a blend of clay and clinker, she found she could supercharge the reaction and boost the strength of concrete. “We got this sensational improvement,” Scrivener recalls. “Then we asked ourselves, ‘What do we do now?’”

She started talking with producers and proselytizing at conferences and trade shows. The initial reaction was skeptical. Intense competition in the cement industry has driven down margins, and many producers have shuttered research labs, so few were keen on anything that might raise costs. Scrivener eventually found groups in India and Cuba that were interested and managed to convince a few producers to try it.

“Karen is the driving force, our mentor and guide,” says Soumen Maity, a researcher with an Indian non-profit called Technology and Action for Rural Advancement and the leading LC3 evangelist in that country. “You can say she’s the engine of the train, and we’re all rallying behind her, providing additional steam.”

As she worked to develop a competitive product, Scrivener encountered a host of setbacks. An early concern was that clay can give concrete a reddish tint. While some buyers might like that, it diverges from the traditional grey. So Scrivener’s team looked to centuries-old brick-making methods to eliminate the problem by tweaking the way the clay is cooled after heating.

And producers frequently made only cursory efforts to find the necessary clay before deciding they didn’t have any. Scrivener’s response was a program to evaluate clay sent in by anyone around the world. She got roughly 50 submissions from about 20 companies and found that almost all had sufficient levels of kaolin, the mineral that makes clay sticky.

“Even though these clays have different characteristics and they’re very complicated, there’s a single determining parameter that you can measure simply, and that’s the kaolin content,” she says.

Still, her first real industrial test was a brush with disaster. Scrivener had been working with Martirena’s group in Cuba, which had mined 300 tons of clay and shipped it to a Soviet-built cement plant at Siguaney, a dusty interior town halfway between Havana and Santiago. When the clay arrived, the region was in a drought and there wasn’t enough water for processing. Then a hurricane struck, flooding the area. When Martirena finally began burning the clay months later, protective bricks inside the kiln started to fall off. Scrivener recalls seeing big chunks of brick in the burned clay, and assumed the experiment would fail. But the Cubans ground the mixture, bricks and all, and made a workable cement.

“If they could do it in this situation,” she says, “they can do it anywhere.”