Aqua Metals is changing how electric vehicle (EV) battery manufacturers make batteries. The Reno, Nevada-based company says it’s the only firm in the world that recycles critical materials from used EV batteries for use in new ones. This closed-loop metal recycling process sustainably removes raw rare earth materials such as cobalt, nickel, manganese, and lithium from discarded batteries so they can be used again.

“This is an unprecedented accomplishment for Aqua Metals and for the global push toward electrification,” Steve Cotton, president and CEO of Aqua Metals, said in a December 2022 statement. “We believe that Aqua Metals is the first company to take a vision beyond the laboratory by establishing an industrial-scale, dedicated, U.S.-based recycling facility, built to continuously produce metric tons of high-purity minerals from spent lithium-ion batteries.”

Video Courtesy Aqua Metals

As the demand for EVs skyrockets, the need for batteries for those vehicles has also increased. In fact, by 2030, the International Energy Agency projects that EVs will account for more than 60% of global car sales. Each of those new EVs needs a battery, which relies on rare earth metals to operate.

The processes associated with metal extraction are the principal causes of environmental concerns about metal mining. It can take a half million gallons of water to mine a ton of lithium, which often causes pollution of nearby waterways. And the concerns don’t stop there. EV batteries only have a lifespan of as little as 10 years and are generally discarded in landfills, where they leak toxic chemicals into the environment.

That’s where Aqua Metals steps in. The company’s AquaRefining technology uses electroplating to selectively recover critical metals from shredded used lithium-ion batteries called “black mass.”

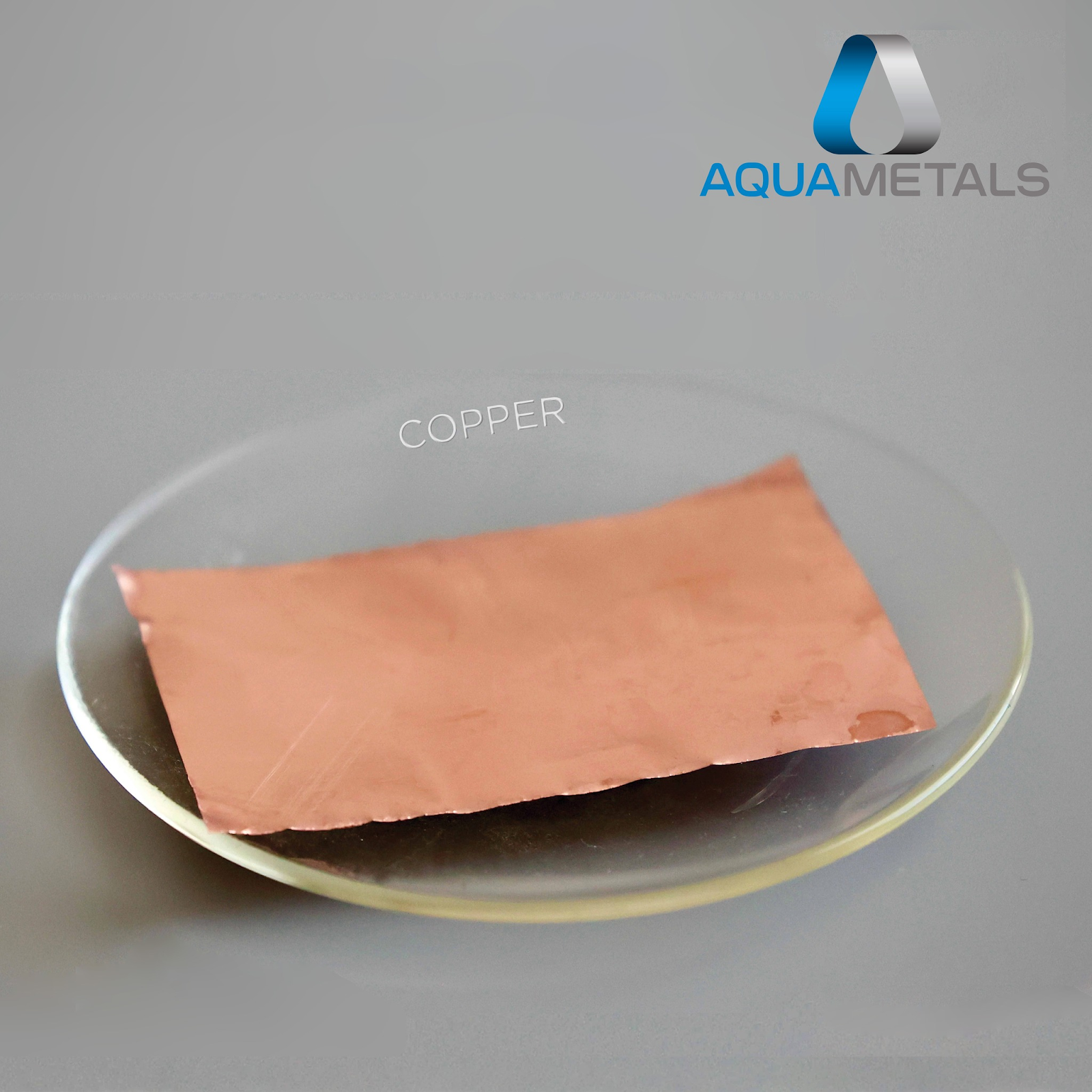

This material is run through a filter press, removing graphite and any aluminum remnants. After that, the copper is electroplated.

An AquaRefining pilot was commenced in December 2022 at the company’s lithium-ion battery recycling facility at its Innovation Center. The facility became fully operational in the summer of 2023, transitioning to a 24-hours-a-day, five-days-a-week schedule.

Photo Courtesy Aqua Metals

“Recycling metals is not difficult, per se, but to do it sustainably can be a challenge,” Cotton told Sustainable Brands in 2023. “Our innovation takes a well-understood technology pathway and applies it in a novel way to selectively recover critical metals from spent batteries.”

“This enables us to recover high-purity metals — as we quite literally plate them, atom-by-atom, using electricity,” he continued. “Combine this with our patent-pending, unique process for recovering lithium in the form of hydroxide directly, and we can recover all valuable metals contained within lithium-ion batteries (LiB).”

As the United States moves toward a clean energy net-zero carbon goal by 2050, making sure used EV batteries are probably reused is critical.

A clean recycling infrastructure is the only way to adhere to a circular, clean economy without adding additional negative impacts to the air, soil, or water. Aqua Metals’ unique process is a turning point in EV battery recycling that can have a significant effect on a sustainable future.

Photo Courtesy Aqua Metals Inc

“The environmental and community impacts of sourcing critical minerals for the clean energy economy are well documented,” Dave McMurty, Aqua Metals’ chief business officer, said in remarks made at the Asia Pacific Economic Cooperation (APEC) Multistakeholder Forum in November 2023. “By pioneering advancements in sustainable recycling technology, we are enabling the circular battery economy and decarbonizing large portions of the clean energy supply chain, setting a new paradigm for the industry — one that minimizes the environmental impacts of critical minerals and offers equitable economic opportunities to host communities.”