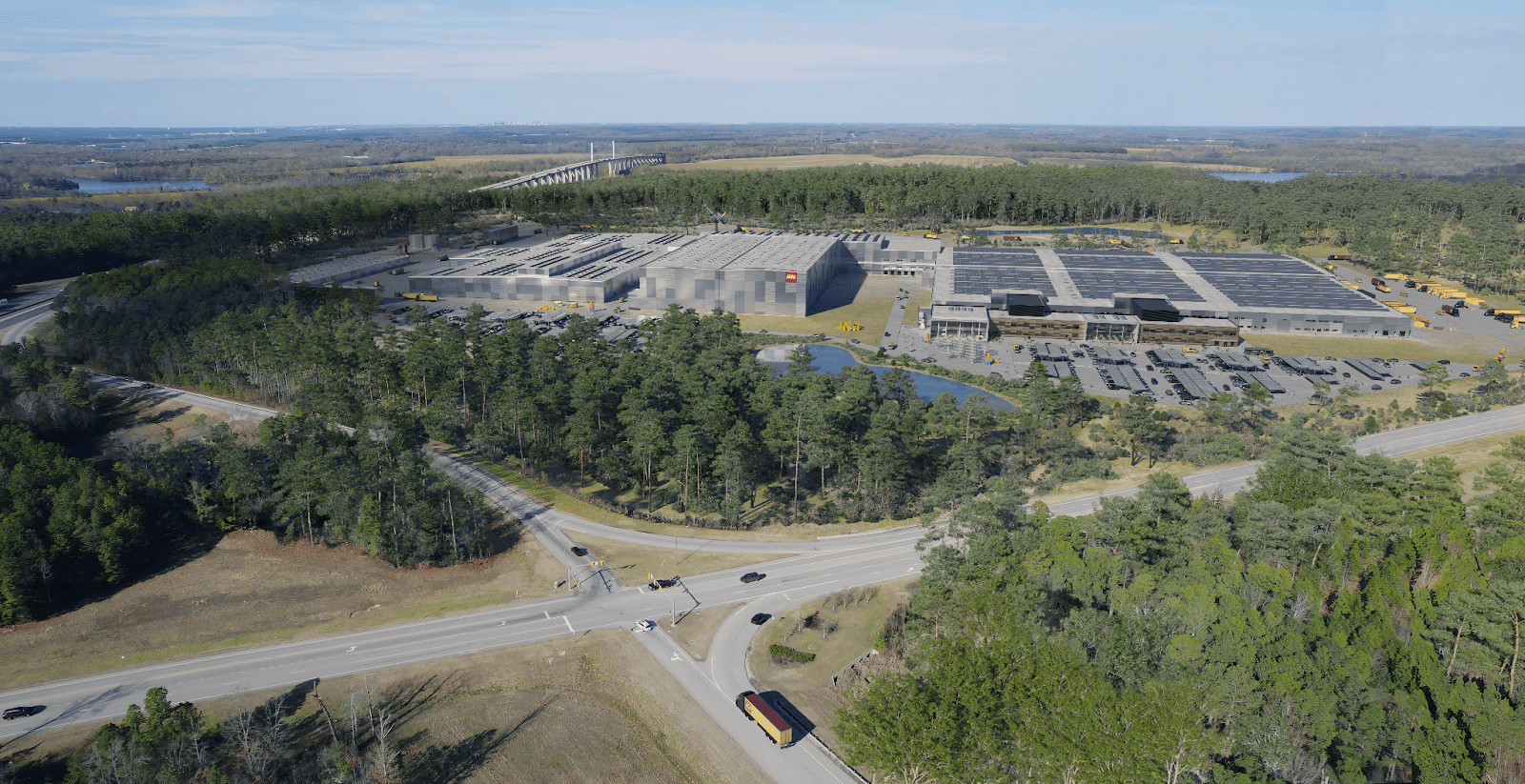

LEGO Group is investing $1 billion to build its first factory in the United States. The new site’s location in Chesterfield County, Virginia, was chosen due to its close access to multiple transportation networks. Niels Christiansen, CEO of LEGO Group, spoke on the location: “The location in Virginia allows us to build a solar park which supports our sustainability ambitions and provides easy links to country-wide transportation networks. We are also looking forward to creating fantastic employment opportunities for the people of Virginia.”

This move follows LEGO’s widespread mission to shore up supply chain issues brought about by the global pandemic.

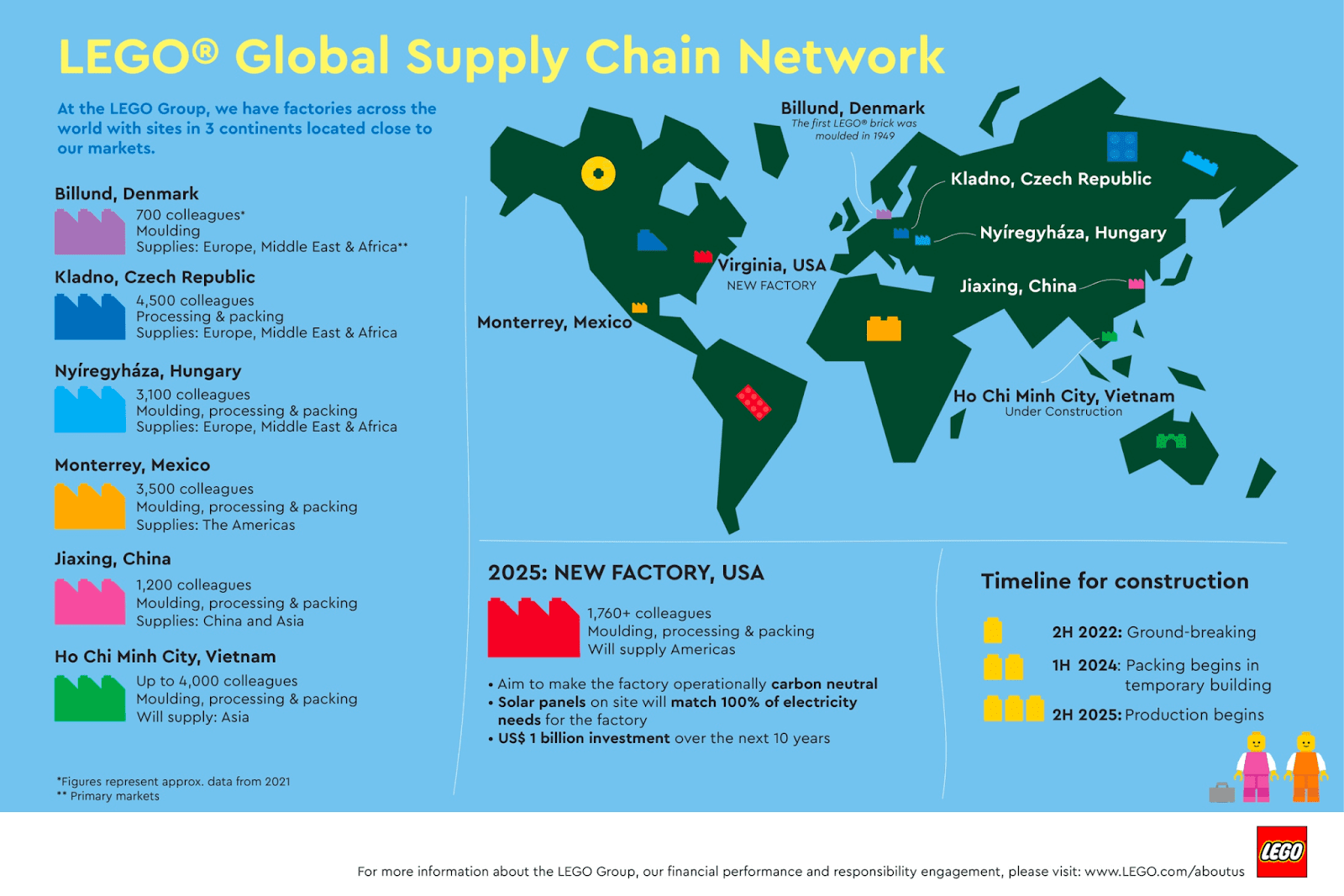

This will be LEGO’s 7th factory worldwide and its second in North America. While LEGO’s Monterrey, Mexico factory currently serves the U.S. market, the Virginia factory will take over production in the U.S. market, currently LEGO’s second-largest domestic market. The press release also stated that the Monterrey facility “will be expanded and upgraded to meet growing demand for LEGO products.”

LEGO’s headquarters in Enfield, CT, used to produce 100,000 LEGO sets per day but closed production in 2007. The new facility will mark the first time in the past 18 years that Legos are being produced in the U.S. Carsten Rasmussen, chief operations officer at LEGO Group, discussed the sustainable benefits of the location, “Our factories are located close to our biggest markets, which shortens the distance our products have to travel. This allows us to rapidly respond to changing consumer demand and helps us manage our carbon footprint.”

LEGO employs approximately 2,600 people in the U.S across its headquarters and 100 storefronts, and its new facility will create around 1,760 new jobs in the next ten years. A temporary facility will open in a nearby building early in 2024, creating 500 jobs until the main facility begins production in the second half of 2025.

The new factory will be carbon neutral, following LEGO’s recent announcement to build a carbon-neutral factory in Vietnam. LEGO has recently pushed for sustainable initiatives, such as its pledge to use only recycled or renewable materials in all packaging by 2025 and committing to making all of its core products from sustainable materials by the end of the decade.

An onsite solar park is a key component of the facility’s carbon neutrality; in a press release, the company says, “100 percent of its day-to-day energy needs will be matched by renewable energy generated by an onsite solar park.” Construction of the 1.7 million square foot facility will begin in the fall of 2022. Once construction is finished, LEGO plans to receive a Gold LEED certification for the building.

LEGO will utilize its state-of-the-art molding technology to ensure the products meet safety and quality standards. The process involves melting different colored granules at 450 degrees Fahrenheit, feeding them into molds shaped like LEGO bricks, and cooling them. The process is almost fully automated, and it needs to be: LEGO makes around 125 million individual pieces each day. In 2025, a portion of them will be shipped out from Chesterfield, VA.