Construction is an industry still experimenting with ways to use more eco-friendly materials. Traditional concrete requires hefty amounts of water, sand, and other resources to create a solid base for buildings.

What if I told you there’s an alternative to concrete made from hemp? What if I told you it’s stronger than concrete and more fire-resistant? Hempcrete is a construction material that we could see in American buildings for years to come.

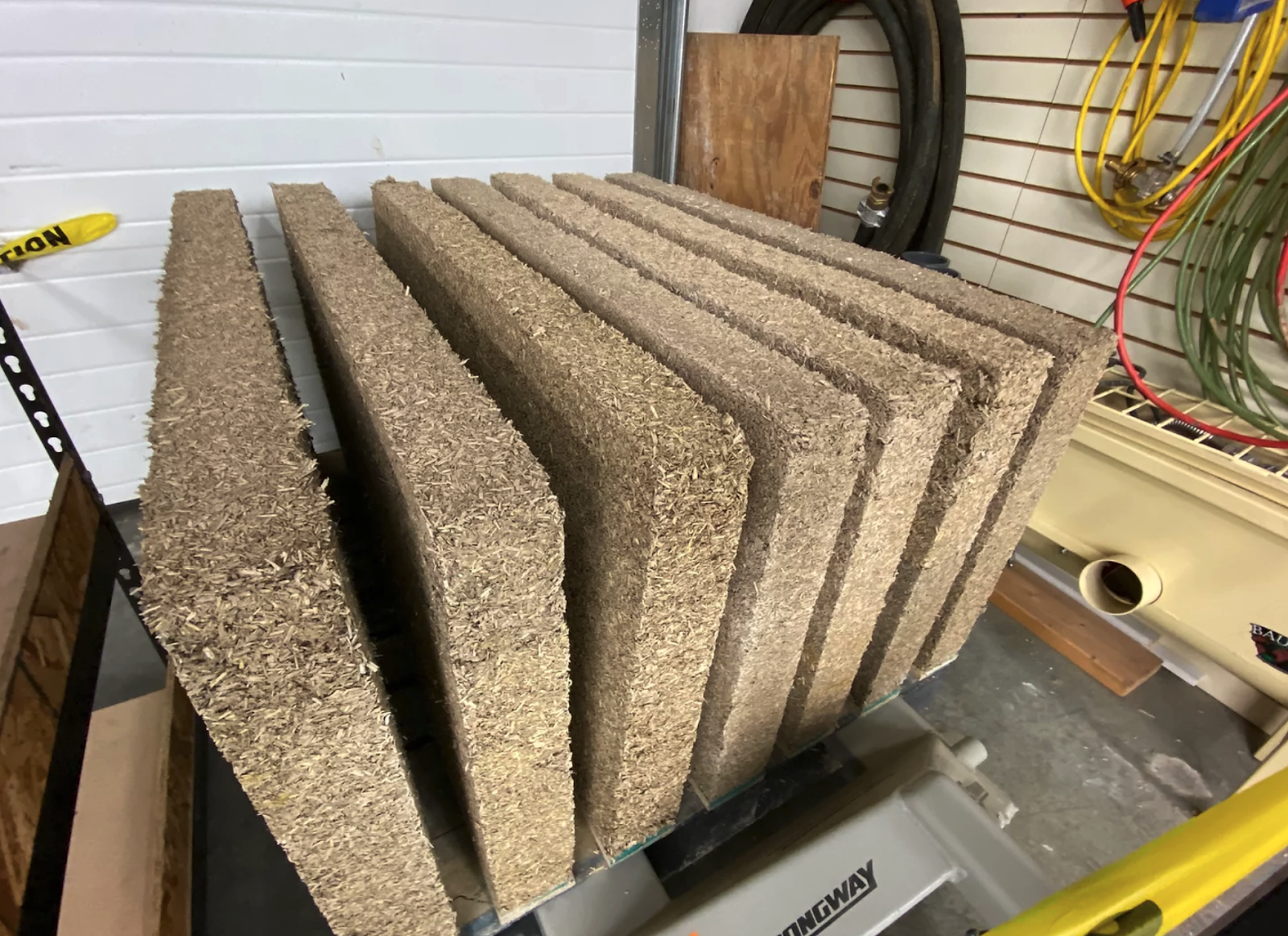

It’s created from a combination of hemp stalks, lime, sand, and pozzolans — the chemicals used to make insulation. The revolutionary material received approval in September 2022 from the International Code Council for domestic residential construction. Only Wisconsin dissented in the 49 out of 50 states who sought approval. The addition will be reflected in the 2024 International Residential Code when it’s published this year.

Hempcrete has been used in France for over two decades, while Canada has utilized it over the last few years. In fact, it has advocacy groups that have pushed American regulators to allow it to be used more prominently.

Photo Courtesy Hempitecture

Essentially, hempcrete functions similarly to cob and straw bale infill material. Its ability to retain moisture and thermal heat and sequester carbon dioxide (CO2) sets it apart from concrete. The organic substance (hemp) captures CO2 in the air while keeping a home comfortably warm. It’s also easier to mix than standard concrete, and its lightweight density makes it easier to transport and layer during construction. A series of rods is weaved throuegh the blocks to keep it packed tightly upon layering.

Despite its uniquely sustainable properties, U.S. building regulations made building and permitting hempcrete structures difficult. However, advocates like Matt Marino of Homeland Hempcrete in North Dakota said the approval “helped add legitimacy to our craft. It is a tool for us to standardize our deliverable.” Policies like these building codes could shift how smaller American houses are built.

According to Hempbuild Magazine, the building material will likely be used in areas with a low seismic activity that doesn’t require engineering to keep houses up. If a construction company can easily erect a structure with the blocks, it will save time and money on labor and supplies. Construction sites will be able to offset carbon emissions thanks to the sequestration properties of the substance.

Photo Courtesy Hempitechture

How will it fare against natural disasters or fires? Hempitecture, an Idaho hemp-based architecture firm, tested whether hempcrete was fireproof. In 2020, the firm stated on its website that the material recorded a 0 rating on the Flamespread and Smoke Development scale when put up against 575-degree heat. According to the company, fire testing on hempcrete has occurred in France and the U.K. for years.

Additionally, it’s relatively resistant to wind and rain, but take care when installing not to put the hempcrete blocks on ground level, as it can still rot from water damage and damp conditions.

The approval for hempcrete for residential construction was a huge win for architects who want to use more sustainable insulation and building materials. The next big step will be winning approval for commercial sites. However, the International Code Council will review guidelines in 2025, meaning there is a chance it will be available for new commercial developments down the line.

Either way, there is an air of excitement with hempcrete’s residential space approval. Henry Gage Jr., head of the U.S. Hemp Builder’s Association, summed it up nicely: “With this vote, hemp-lime construction has moved to the mainstream, creating a new era of investment, research, architecture, and construction.”