On Oct. 22, the United States Department of Energy (DOE) announced $428 million in funding for 14 clean energy manufacturing projects. By filling gaps and resolving vulnerabilities in the domestic energy supply chain, they will serve an important national security function.

“Each project further positions the United States to win the competition for the 21st century and strengthen our national security by building supply chains for existing and emerging technologies in America, built by American workers with American materials,” the DOE explained in a press release.

The department’s Office of Manufacturing and Energy Supply Chains selected the projects in the second round of the Advanced Energy Manufacturing and Recycling Grant Program, which is funded by the Bipartisan Infrastructure Law.

The $750 million program awards grants to small and medium-sized manufacturers whose gross annual sales total less than $100 million, whose yearly energy bills are more than $100,000 but less than $2.5 million, and which employ fewer than 500 employees at the plant site.

Photo Courtesy EnergyCommunities

The businesses can use the funding to build, re-equip, or expand plants that make or recycle advanced energy technologies or low-carbon materials, or to re-equip plants with equipment that can reduce their emissions. The facilities must be located in communities with decommissioned coal mines or power plants, thereby ensuring that they will continue to serve an essential function throughout the clean energy transition, just as they once formed the “backbone of the country’s energy sector.”

“The transition to America’s clean energy future is being shaped by communities filled with the valuable talent and experience that comes from powering our country for decades,” Jennifer Granholm, Secretary of Energy, noted in the press release. “By leveraging the know-how and skillset of the former coal workforce, we are strengthening our national security while helping advance forward-facing technologies and revitalize communities across the nation.”

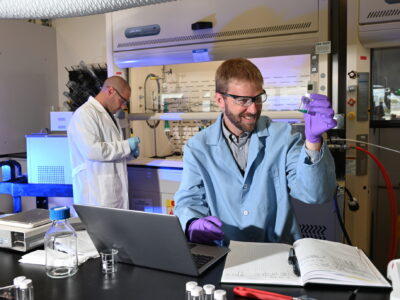

Photo Courtesy National Renewable Energy Laboratory

However, this is not the first set of projects selected through the program. In November 2023, the DOE announced $275 million for seven projects spanning seven states, some focusing on clean energy. Boston Metal said it planned to use its award for a new facility in Weirton, West Virginia, that would churn out materials needed to produce fuel cells, green steel, and various forms of renewable energy.

Others zeroed in on batteries or the grid. MP Assets Corporation proposed a new project in Virginia that would make lithium-ion battery separators for electric vehicles (EVs). CorePower Magnetics, Inc. earmarked its federal cost share to retrofit a former coal power plant in Pittsburgh facility to melt and cast advanced magnetic amorphous alloys for transformers and motors. Nanoramic Laboratories wanted to build a lithium iron phosphate battery electrode manufacturing plant in Bridgeport, Connecticut.

Two awards were in the category of building retrofits. Alpen High-Performance Products, Inc. plans to use its award to retrofit factories in Louisville, Colorado, and Vandergrift, Pennsylvania, to produce insulated glass units for windows.

Meanwhile, LuxWall Inc. aims to build a new factory in Detroit to replace a former coal generation plant and make vacuum-insulated glass window units.

At the time of the announcement, the DOE expected the projects to spur more than $600 million in private sector investments into the small and medium-sized awardees and support nearly 1,500 jobs in total.

Photo Courtesy Alpen High-Performance Products

Meanwhile, the new projects most recently selected in the second round will lead the private sector to invest more than $500 million in small and medium-sized businesses in 15 communities home to closed coal mines or coal power plants, supporting more than 1,900 jobs. In fact, every project will be accompanied by a community benefits plan, and five of the projects will be located within or near disadvantaged communities.

While the projects span five supply chains, the production of low-carbon materials is the biggest sector intended to receive support.

For example, CleanFiber Inc. proposed building one 60,000-square-foot plant in Ennis, Texas, and another in Chehalis, Washington, that would both turn recycled cardboard into carbon-negative cellulose insulation.

The DOE allocated $10 million to the facilities, which together are expected to weatherize more than 20,000 residences annually and hire 66 temporary contractors during construction and 80 employees permanently, with 40% of those opportunities destined for disadvantaged former coal industry employees.

Hempitecture Inc. was selected to receive $8.42 million for a new plant in Rogersville, Tennessee, that would process and manufacture industrial fiber hemp products, replicating a process already in operation at its facility in Idaho. It expects to make 7.5-millimeter pounds of product annually with a carbon intensity that is 60 to 80% lower than competing insulation products. It hopes that “Project Appalachian Green Fiber” will create 12 to 15 construction, 25 permanent, and possibly 50 farming jobs, with a wage floor that is 15% above the industry hourly rate.

Photo Courtesy Hempitecture

A subcategory of this section zeroed in on cement, in particular. Furno Materials, Inc. was allocated $20 million for the first-ever production facility for circular, low-carbon cement, located next to and as a supply source for Ozinga’s concrete plant in Chicago. By using recycled industrial waste to replace 44% of what would otherwise have been virgin raw material, Furno’s process reduces carbon intensity by 47% and other pollutants by more than 90%. Eighty new employees will be needed to make it a reality, with many sourced by teaming up with local educational institutions.

Terra CO2 Technology Holdings, Inc. plans to use its $52.6 million award to build a new manufacturing plant in Magna, Utah, located near Rio Tinto’s Kennecott mine, the biggest North American copper mine. It will use its mine tailings to make 240,000 tons of Supplementary Cementitious Material annually, an alternative to Ordinary Portland Cement that costs less and emits 70% fewer emissions. Plus, the company will support 61 jobs with wages higher than the national 75th percentile and provide construction training to 144 individuals from underrepresented populations.

Finally, Urban Mining Industries wants to use its $37 million to launch manufacturing facilities in Baltimore and Indiantown, Florida, at which it will use learnings from its Connecticut plant to divert recycled glass from landfills.

Instead, the glass will become Pozzotive®, a ground glass pozzolan with a carbon footprint that is 94% lower than the cement traditionally used in concrete and will lessen occurrences of the heat island effect. Together, the facilities will support 40 new jobs.

Photo Courtesy Terra CO2 Technology Holdings

Several other selections targeted the battery industry. Anthro Energy, Inc. was selected to receive $24.9 million for a Louisville, Kentucky, facility retrofit that will enable it to produce advanced electrolytes for lithium-ion batteries. It will churn out 12,000 metric tons of the material annually and create 400 construction and 115 permanent jobs.

Moment Energy Inc. will use its $20.3 million to build the U.S.’s first UL1974 Certified manufacturing facility in Taylor, Texas, to repurpose EV batteries, turning them into battery energy storage systems.

It estimates its annual output will reach 1 gigawatt-hour (GWh) and create 50 construction and 200 permanent jobs.

Finally, Sparkz Inc. has earmarked its $9.8 million for a first-of-its-kind facility in Bridgeport, West Virginia, that will produce 4,000 tons of battery-grade iron phosphate annually. It will be used in lithium-ion phosphate batteries that will help displace 22,000 internal combustion engine cars per year, in addition to supporting 75 jobs.

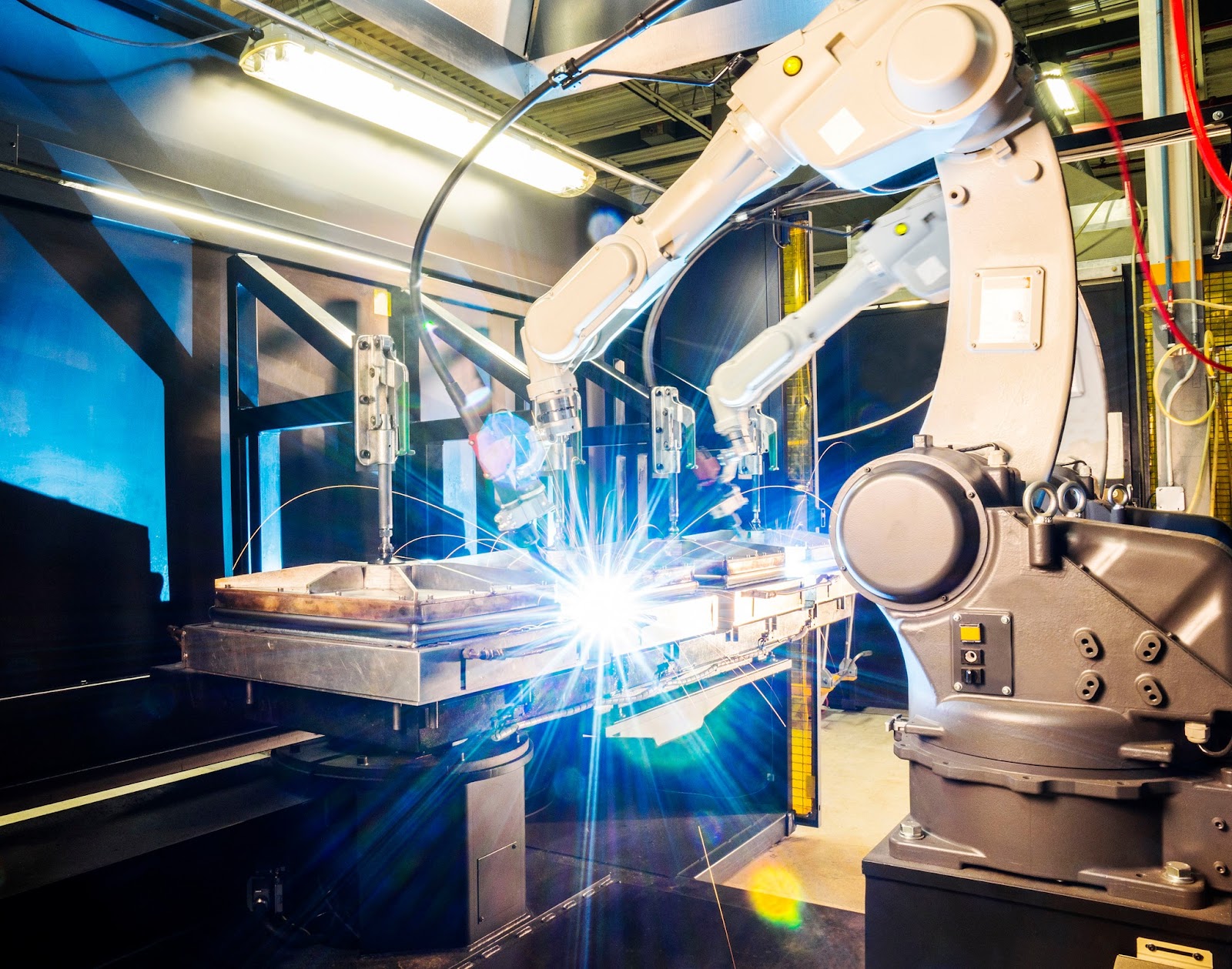

Grid components were another popular category in the selections. For example, TS Conductor Corp. has $28.2 million to annually manufacture advanced conductors, including High Voltage Direct Current (HVDC) conductors in Erie, Michigan, to contribute to 8,000 miles of the grid. It will also create 425 construction and 162 operating jobs. MetOx International, Inc. is funneling its $80 million into an advanced superconductor manufacturing facility, specifically for high-temperature superconducting wire, in the Southeast called Project Arch, which will hire 230 local employees.

Photo Courtesy TS Conductor Corp.

If funding is committed, each of these new conditional selections has the chance to reinvigorate former coal communities and contribute to developing a more energy-independent and climate-friendly country.