California-based knitwear manufacturer FutureStitch is known for its zero-waste manufacturing system. The company recently teamed up with the San Diego Workforce Partnership to employ formerly incarcerated women at the Oceanside plant. These employees also have access to a learning curriculum, coaching, and housing assistance.

It all started because founder Taylor Shupe got in trouble as a teenager but recognized that his family’s privilege made it easy for him to get out of it. Since then, he knew he needed to give back.

New hires will be able to develop a wide range of workforce skills, including marketing, sales, and company operations. They will have access to life coaches and psychiatrists.

Each woman is given a Chromebook, which allows access to basic computer skills instructional programs. The goal is to ensure each new employee can use common employer applications such as Google Docs and various email programs. Each participant can tailor the courses to what she wants to learn most.

Employees earn credit at the end of each course, which can be turned in for various gift certificates and other prizes. FutureStitch hopes to employ at least 50 formerly-incarcerated women by the end of summer 2023.

“We can foster an entrepreneurial mindset and confidence, as well as soft and hard skills that can lead to better employability,” Shupe told Forbes. “The goal is to empower people who have been left out or even left out of the system.”

The goal of the hires is not only to give back to the community but to increase employee retention and productivity and to attract more talent.

“You have this huge working population that has been left out,” he continued. “We knew we could build something that empowered them.”

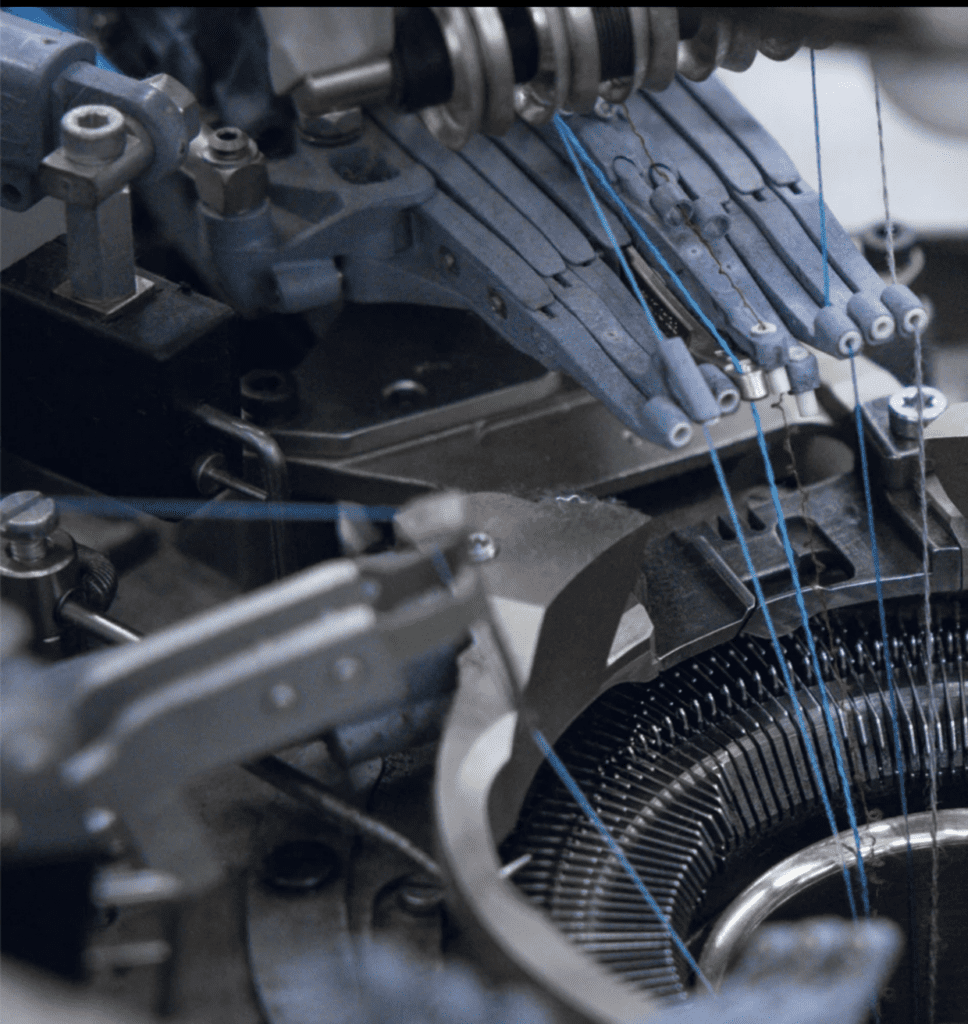

FutureStitch started in 2017, breaking sustainable ground using a highly-automated process known as circular knit. This zero-waste system means less labor is needed to create a product.

Sustainability has always been at the forefront of FutureStitch’s mission. Its manufacturing facility even received the highest LEED designation possible, making it the highest-scoring building among any knitwear manufacturer across the globe in 2020. The company uses green transportation, lower water and power approaches, and low-impact construction in its facilities. For FutureStitch, it’s always been about far more than making shoes and socks.

“Since our founding, FutureStitch had an equal focus on producing high-quality products and raising global manufacturing standards,” Shupe said in a statement. “Addressing society’s most pressing issues — such as combating climate change and providing meaningful employment with living wages — should be a primary goal for all manufacturing companies.”

“Our Platinum LEED certification demonstrates that it is possible for any manufacturer to move beyond aspiration and take action to create a workplace that both engages employees and reduces its impact on the environment,” Shupe continued.