One of the biggest challenges in the fight against climate change is figuring out how to curb industrial pollution. According to Coolbrook, a Finnish technology and engineering firm, about one-quarter of global carbon dioxide (CO2) emissions come from heavy industry. Most of these emissions are from burning fossil fuels during industrial process heating — and those emissions are growing every year.

Coolbrook aims to help reverse the trend through an innovative “rotating technology” called RotoDynamic that decarbonizes major industrial sectors by replacing fossil fuels with electrification powered by clean and renewable energy. The Helsinki-based company claims RotoDynamic is the “only technology in the world” capable of cutting “30% of industrial CO2 emissions and 7% of global CO2 emissions annually.”

Photo Courtesy Coolbrook

According to Coolbrook’s website, the technology combines space science, turbomachinery, and chemical engineering to replace fossil fuels across major industrial sectors. It has two main applications: RotoDynamic Reactor (RDR) to reach 100% carbon-free olefin production and RotoDynamic Heater (RDH) to provide carbon-free process heating to iron and steel, cement, and chemicals production.

“Coolbrook aims to fundamentally transform the way heavy industries operate,” Joonas Rauramo, Coolbrook CEO, said in a statement on the website. “With our revolutionary technology for industrial electrification, we enable significant decarbonization and bring a disruption to the status quo.”

Photo Courtesy Coolbrook

For Coolbrook to do that, it needs to join forces with major industrial players willing to adopt its technology. The company has made great progress on that front since development of RotoDynamic Technology began in the late 1990s.

As Fortune reported in November 2022, Coolbrook has forged partnerships with global industrial giants such as ABB Group, Shell Global, and Cemex to help them transition to electric heating processes from traditional coke and gas-fired furnaces in industrial cement production.

The company claims the process could save 2.4 billion tonnes of carbon emissions a year.

This effort is an important step because of the nature of the cement industry. One reason the material is so hard to decarbonize is because extreme temperatures are needed in the production process, Fortune reported. Historically, only fossil fuels could create those extreme temps.

Photo Courtesy Coolbrook

But Coolbrook’s RotoDynamic Technology provides an alternative. According to the company’s website, when the technology is implemented at scale, it has the potential to reach temperatures of 1700 degrees Celsius. That was one of the messages Coolbrook drove home during the 2022 United Nations Climate Change Conference, commonly known as COP27.

“The key reason why we wanted to be at COP27 was to bring the message that there are technologies available to solve the problem in industries that are considered ‘hard to abate’ or impossible to electrify, that there are technologies that can help in solving these challenges,” Rauramo told Fortune.

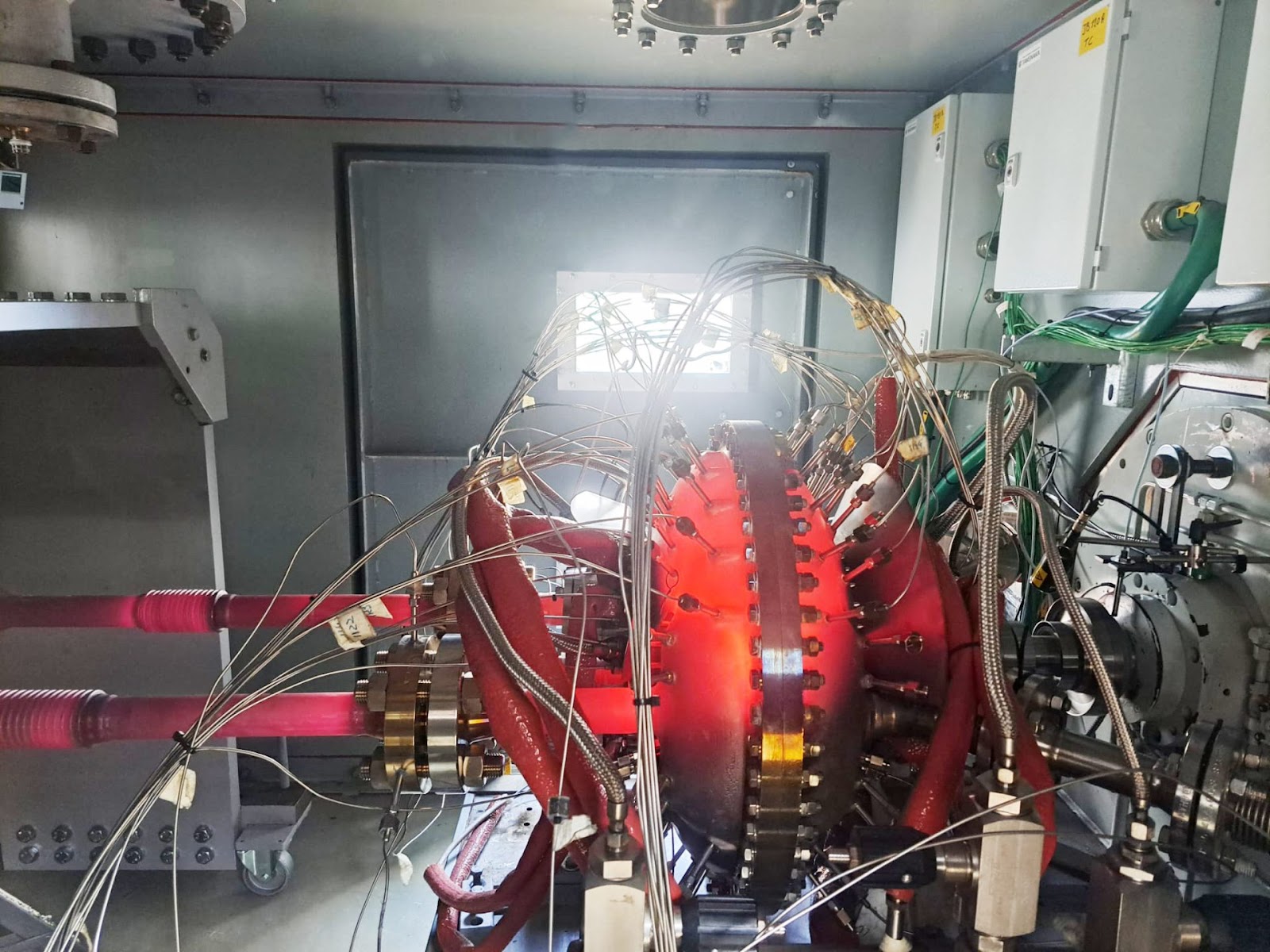

Coolbrook’s RotoDynamic Heater doesn’t need combustion to generate heat. Instead, it accelerates “air to generate friction and heat, forming a kiln powered by renewable electricity,” according to Fortune.

Photo Courtesy Coolbrook

“If you think of the machine, it looks and works a little like a reverse jet engine,” Rauramo said. “There is an electric motor that is rotating these blades, and they are used to accelerate air to supersonic velocity, which is then slowed down again rapidly, converting kinetic energy into heat.”

Coolbrook continues to refine and advance the technology. In September, the company announced that it successfully completed the first phase of large-scale pilot testing for its RotoDynamic Technology at the Brightlands Chemelot Campus in the Netherlands.

Coolbrook spent much of the year running a test program to demonstrate the RotoDynamic Heater technology for electrification and decarbonization of high-temperature industrial processes.

The pilot testing has reached the level of 1000 degrees Celsius, which “already exceeds the temperature range of conventional resistive heaters by several hundred degrees,” according to a press release.

In a joint statement, two of Coolbrook’s university partners – Dr. Liping Xu and Dr. Budimir Rosic – said RotoDynamic Technology is set to bring forth a “fundamental and revolutionary impact on the petrochemical industry and other high-temperature industries for greenhouse gas reduction.”

The successful completion of the first test phase also provides “a solid basis for Coolbrook’s engineering, manufacturing, and supply of industrial-scale equipment to customers,” according to the press release. The company aims for the technology to be operational in 2024, with full commercial deployment expected around 2025.